Are you familiar with terms such as “paper grade kraft pulp” and “ionic liquids”? Do you have a clue what “cellulose pre-treatments and dissolution” is or how you can spin man-made cellulose fibres? We (GRETE communication team) didn’t – until we met GRETE.

GRETE is an international collaboration focusing on the further development of sustainable processes for the textile industry, that means a lot of Research and Development (R&D) is going on here with a lot of experts talking about “technical stuff”. The exciting aspect of a transdisciplinary network, like the GRETE consortium, is that you have a lot of professionals approaching the same topic from a different perspective; sometimes challenging to bring everyone on the same page, but offers the chance to all participants to broaden their knowledge, to detect new collaboration opportunities and to contribute to strengthening Europe’s innovation potential. But let’s get back to the “technical stuff”.

GRETE is about three key terms:

- Man-made Cellulosic Fibres (MMCF)

- Paper pulp

- Ionic liquids (IL)

The final goal in GRETE is to produce man-made cellulosic fibres (MMCF) that are commercially relevant while contributing to reduce the environmental footprint of the textile industry. Therefore, the consortium partners are benchmarking the future GRETE MMCF production processes and fibre performances against the current market-dominant Lyocell fibres, in order to implement more sustainable production technologies and tailored fibre properties for less water-intensive textile transformation steps.

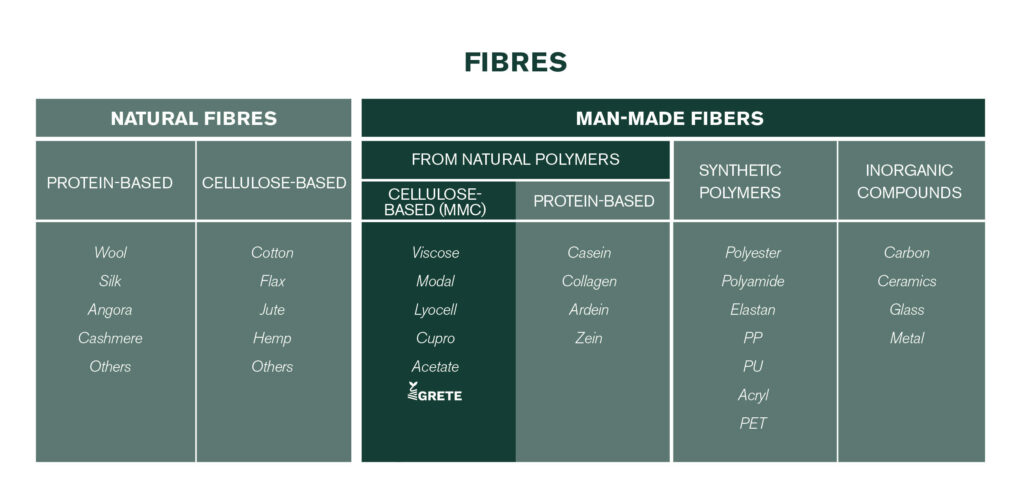

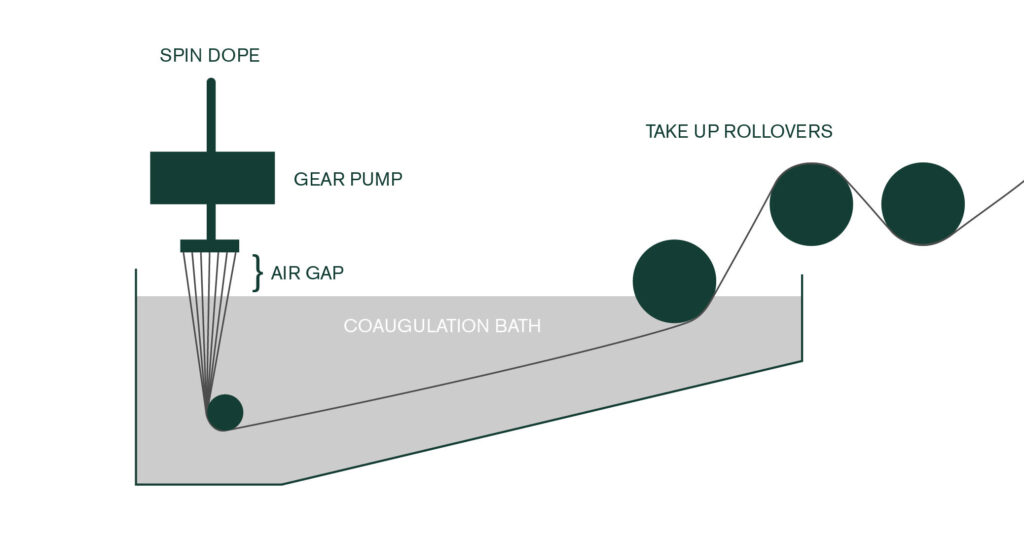

Man-made cellulosic fibres are a derivative of wood pulp and other natural plant materials, where the cellulosic elements provide the raw material that is transformed into an extrudable component (polymer dope or solution) for the subsequent Wet- or Dry-jet wet spinning process, as used in the production of Viscose fibres (Wet- spinning) and Lyocell fibres (Dry-jet wet spinning). Currently, cellulose in dissolving pulp quality is needed as the raw material for these processes, and quite harmful chemicals are applied.

GRETE aims at optimising the current MMCF value chain and lowering the environmental footprint by acting on two parameters in the spinning process:

- opening up the raw material base by using never dried paper pulp in the process: a widely available, thus cheaper and most of all less impacting raw material than dissolving pulp;

- substituting the harmful chemicals with ionic liquids: they are currently more costly than the traditional chemical components, but are an excellent solvent for cellulose, and above all non-toxic and recyclable.

Want to know more about these terms? Follow us on social media Facebook and Instagram, and don’t forget to subscribe to our newsletters.