The GRETE consortium is working towards opening up wood pulp as a raw material for man-made cellulose fibres. The partners are convinced that having access to this broadly available source of cellulose will lower the environmental impact of regenerated fibre production while offering great benefits for the European textile industry, strengthening the already existing wood-to-textile value chain.

Currently the raw material base for the production of man-made textiles from wood is limited, as only highly processed and expensive dissolving grade pulps are used industrially. GRETE will introduce disruptive technologies that enable the use of never-dried paper-grade Kraft pulps from softwood and hardwood as a raw material for man-made textile fibres. This Wood pulp is already the starting material for a multitude of outputs of bioproduct mills which are able to transform 100% of the valuable properties of wood into different products such as cardboard, paper, tissue, packaging solutions and eventually textile fibres.

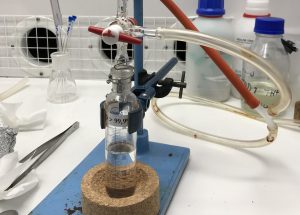

GRETE aims at overcoming the bottlenecks identified in the wood-to-textile value chain, one to be opened up, starting from the raw material, is the presence of hemicellulose in Kraft pulps. Understanding the role of hemicellulose in fibre regeneration and how pulp pre-treatments do affect hemicellulose, is widely studied in the GRETE R&D streams. The scientists involved in GRETE are developing innovative technologies for enzymatic pre-treatment and chemical modification of pulps prior to cellulose dissolution. The modifications can enable water-scarce and thus more sustainable textile manufacturing, while including the otherwise discarded hemicellulose into the regeneration process of fibres.

Keep on following the project to discover the progress in overcoming the identified bottlenecks in the wwod-to-textile value chain: subscribe to the newsletter here.